Availing service of Fast Prototype PCB is essential for every electronic product manufacturer as through this service, and he can save his investment on a complete production run. Besides, getting an idea about errors and faults of designs helps him make changes on time. A Prototype PCB is usually available in three different layers of format.

Single side PCB

The first device used to create an interconnection and assembly of electronic components was the single side PCB. Through it, engineers can form a functional and cohesive operating system. This type of prototyping is typically used for the consumer electric industry.

Double Side PCB

An electronic product might require intricate designs, and therefore manufacturers place an order of double side PCB. In this design, two different PCB sides are layered together while connected via Plated Through Hole.

Multi-Layer PCB

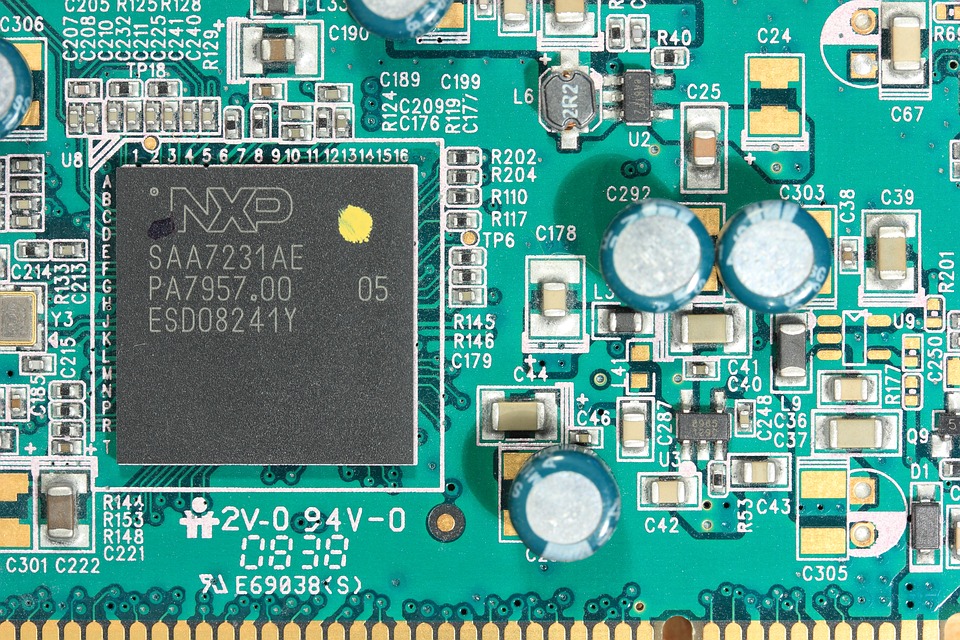

It is a more complicated design than other types of PCB. More than two PCB layers are well-connected in it. Circuit layers are available on both top and both sides of PCB, while each layer gets its connection via PTH (Plated Through Hole).

PCB Prototype Specifications

Every manufacturer of PCB prototypes creates an item based on his customers’ specifications who would define PCB board thickness, minimum hole size, and minimum track or spacing. Besides, it’s vital to choose finished cooper, silk-screening, and surface finishing.

Quality Control

When picking the PCB prototype supplier, one of the most important considerations is to look into quality control testing and check. The manufacturer is interested in quality tests that a supplier performs to ensure top-quality supply of PCB Prototype as per international quality standards.

Circuit board Testing

Once a circuit board is ready, a supplier would run different tests to check its functionality and design perfection. When a manufacturer orders a multilayer PCB, an X-Ray is used to check multilayers’ registration accuracy. A.O.I (Automated Optical Inspection), Impedance Control, and E-Test are the most common industry-wide tests. Some suppliers conduct CCD (Camera Controlled Drilling) that holes are created as per the client’s specifications.

Quality Screen Printing: It’s essential to check what quality of screen printing a supplier offers. The best printing requires supreme quality ink that can provide accessible and readable legend.

Stencil Testings

SMD stencils also go through some rigorous testings to offer only good-quality and fully-functional stencils to manufacturers. They put in place Real-Time Process Control through which they monitor the cutting of each aperture in real-time. Optical sight checking is another standardized test. Suppliers of Fast Prototype PCB also do verification of manufacturing tolerances.