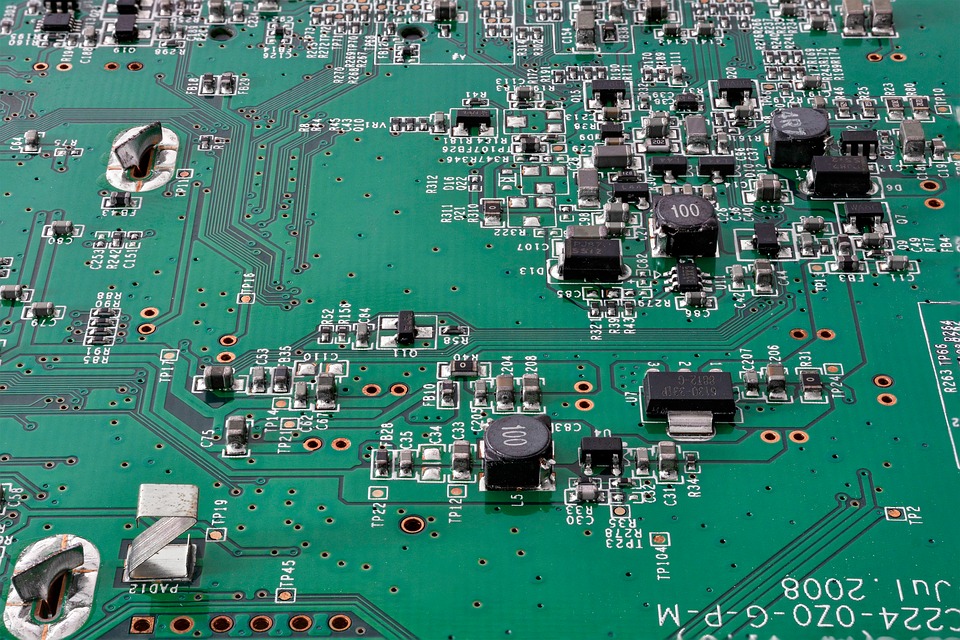

When you think of small Batch PCB assembly services, you probably picture tiny, inexpensive devices suitable for testing and tweaking prototype products. Or maybe you think of low-volume production runs where you’ll make hundreds or thousands of units in a short amount of time. In either case, low-volume production can often be an expensive proposition. Fortunately, there are some good ways to bring down the cost – even without reducing the number of units produced.

Cost-effectiveness

One of the best advantages of low volume small Batch PCB assembly services is that it can ultimately reduce production costs. By using small batch PCB assembly services, you can get just what you need (instead of paying for many identical boards you plan to use for multiple applications) without incurring a high additional cost. This is true regardless of your initial usage, your initial production volume, your final delivery size, or whether or not you intend to sell your product. By investing in low volume, high yield parts, you can save a significant amount of money on initial purchases and final assembly charges. You can also keep a large portion of your investment, which can help with long-term cost management.

Quick Prototype Development

Another advantage of small Batch PCB assembly is that it can often speed up the prototyping process. Often, large-scale production processes can take months or longer simply due to the time required to carefully plan the various phases of production. Using low volume PCB allows you to rapidly build prototypes with a minimal investment in personnel or equipment. This results in prototypes that have been designed and developed to meet your exact specifications, providing an enormous amount of time and money saved.

Multiple Assembly Lines

Another advantage of low-volume PCB assembly services is that they can provide you with several different high-density printed circuit board assemblies produced on a similar design. This can be particularly useful if you need to produce several prototype designs of identical products. The prototype designs can be designed and developed using CAD software, while a high-quality, fully automated machine can make the final production designs. If you find you cannot locate any of these options, you may be able to source a manufacturer or supplier that can assist you with the production of several identical prototype designs.

Reduced Manufacturing Costs

In addition to reducing errors and shortening the fabrication process, the lower manufacturing costs associated with low batch volume assembly means you will be able to pass on the savings to your customers. If you pay a high price for an individual circuit, only the portion that requires production will be produced. Because of this, your overall production cost will be substantially lower.

The other benefit of a lower overall manufacturing cost for your products is that you will save on packaging costs since you won’t need to pay the same amount for individual circuit boards as you do for bulk packages. The combination of both of these advantages means that your customers will be paying a lot less for your products, and you will be able to increase your profit margin.